The question of how to bend rebar without resorting to the help of professional equipment can become an edge not only on construction sites, but also on private buildings, for example, on a private plot. If there is a need to bend steel bars, when there is no access to electric machines at the facility, you can use a hand tool for bending rebar. Today we will talk about simple, but very functional tools from the manufacturer Afacan.

The most common hand tools for bending rebar:

Afacan Rebar Bending Wrench

A special tool that is used for bending steel rods fixed in concrete structures is called a rebar wrench. The material of the key is alloy steel, which is induction—hardened in the area of the working area, which ensures the strength and durability of the tool.

The handle is coated with a special powder paint, has a rubberized tip for a comfortable grip.

The tool range of keys for Afacan fittings has 12 models, which are designed for bending bars with a diameter from 10 mm to 32 mm, in increments of 2 mm. At one time, one key can bend 1 steel rod of a certain diameter. The weight of one key is from 950 g to 7.5 kg, the length is from 710 to 1500 mm.

The tool range of keys for Afacan fittings has 12 models, which are designed for bending bars with a diameter from 10 mm to 32 mm, in increments of 2 mm. At one time, one key can bend 1 steel rod of a certain diameter. The weight of one key is from 950 g to 7.5 kg, the length is from 710 to 1500 mm.

The specified weight and size make it easy to operate the tool and carry it from place to place.

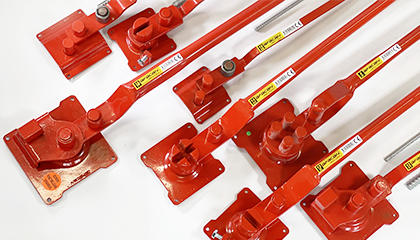

Afacan Manual Rebar Bending Machine

A special tool that is used for bending round, square and strip steel is called a rebar machine. Afacan manual machines are designed for bending rebar in a cold state.

The model range consists of 7 models that bend fittings with a diameter from 6 to 16 mm, and the length of the levers varies from 940 mm to 1430 mm, depending on the model.

The model range consists of 7 models that bend fittings with a diameter from 6 to 16 mm, and the length of the levers varies from 940 mm to 1430 mm, depending on the model.

Before using the manual machine, it should be fixed on a solid horizontal surface with screws or bolts. For a better understanding of the principles of working with the Afacan manual rebar bending machine, we suggest watching the video: →

Advanced ways of rebar bending

Professional methods include the bending of fittings using electric machines. Such devices significantly increase the efficiency of the process, simplify the work and allow you to bend the rebar on an industrial scale. Their use is advisable for large enterprises engaged in the manufacture of reinforced concrete structures, specialized organizations for the production of fittings and on construction sites under a canopy. In private construction, with a small amount of work, it is enough to have a manual machine for bending rebar. For high-quality bending, it is necessary to fix the manual machine correctly on a table or a bed using self-tapping screws or screws that are firmly screwed into the bed.

!!! An important point: you CANNOT weld the machine! You ONLY need to fix it with screws or screws.

!!! An important point: you CANNOT weld the machine! You ONLY need to fix it with screws or screws.

What to choose: a manual wrench or a rebar bending machine?

If there is no need to bend the rebar on an industrial scale, a hand tool will be enough for private construction. The question is which tool should be purchased.

Let's figure it out:

the rebar bending wrench is used for rebar fixed in concrete;

the rebar bending machine is used at the stage of preparation of reinforcement of the structure.

What is bent reinforcement for?

The scope of application of bent steel rods is very wide. During the construction of reinforced concrete structures, the most vulnerable places are considered to be the joints of reinforcement — for example, corners. Creating corners and other structural elements by crossing smooth steel bars is a violation of construction technology. It is in this case that it is worth using solid reinforcement bent in accordance with the required configuration.

In order to bend the rods at home, artisanal, unreliable methods are often resorted to: before bending, a rod is filed or heated with a blowtorch. These actions significantly weaken the structure, negatively affect the strength characteristics of steel products. According to technology, it is necessary to bend the reinforcement only in cold form and exclusively by mechanical means. In this case, the bars retain their original physical and chemical properties and ensure the strength of reinforced concrete structures.

In order to bend the rods at home, artisanal, unreliable methods are often resorted to: before bending, a rod is filed or heated with a blowtorch. These actions significantly weaken the structure, negatively affect the strength characteristics of steel products. According to technology, it is necessary to bend the reinforcement only in cold form and exclusively by mechanical means. In this case, the bars retain their original physical and chemical properties and ensure the strength of reinforced concrete structures.

That is why keys or rebar bending machines are in great demand in high-quality private or industrial construction.